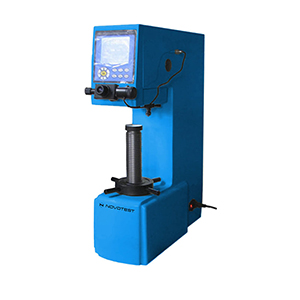

Brinell, Rockwell, Vickers Hardness tester NOVOTEST TS-BRV-C

Digital Brinell, Rockwell, Vickers Hardness Tester NOVOTEST TB-BRV-С implements Brinell, Rockwell, and Vickers hardness test methods in line with ISO 6508, ASTM E10, ASTM E92 and ASTM E18. In this hardness tester, all operations are fully automated so human error doesn’t influence the measurement. TB-BRV-С has high measuring accuracy, and a wide range of applications thanks to three hardness test methods and a wide variety of scales implemented in the device. The device is equipped with a built-in high-precision optical microscope and a large LCD screen, and also a PC connection for the transfer of measurement data. TB-BRV-С is very easy, fast and convenient, no manual tables are used.

Key Features:

Automatic operation and instant display of hardness

The instrument is controlled and configured using an LCD 8-inch touch screen, which greatly simplifies the operator’s work, and the testing process itself is fully automated. The instrument is equipped with various tables for mounting various parts and workpieces. The maximum permissible height of the test object should not be more than 170 mm for Rockwell and not more than 140 mm for Brinell and Vickers. The load and unload mechanism uses a stepper motor drive. Using the Rockwell method the load cell transmits the hardness to the microprocessor control system, which converts the depth of the imprint into hardness units using a special algorithm, and then displays the hardness value on the screen on the front of the hardness tester. The size of the indentation is measured using a precision optical measuring system equipped with three lenses for Vickers and Brinell testing.

Versatility for a wide range of materials

The device is suited to a wide range of materials due to the existence of a variety of methods, scales and test forces. These can be non-ferrous metals like aluminium and its alloys, brass, copper, and tin through steel, cast iron, low carbon steel, and tempered steel, as well as components formed of hard alloys, carbonized, and chemically treated layers, the spectrum is extensive.

Comfort of use and assessment of imprints

Digital Brinell, Rockwell, Vickers Hardness Tester NOVOTEST TB-BRV-С includes an optical microscope that is simple to install. It has two replacement lenses with magnifications of 2.5X and 5X, allowing users to select the most comfortable one for the work at hand. The microscope has a 15x magnification and exterior and internal lighting that lets users see the imprint and the test object vividly. Also, one of the tables has a special sliding stand that makes measurements even easier.

Bright colour display and automatic processing of measurements offer unmet applicability and comfort

The LCD 8-inch touch screen, a big number of hardness scales and Rockwell, Vickers and Brinell indenter with 3 different balls and test forces make TB-BRV-С the most universal and functional bench hardness tester in the world. The high precision microscope with dual backlighting, the special sliding testing table, completely automatic operation, digital display, and built-in printer with the option of data transfer to PC make the device the most advanced, contemporary, multi-purpose and simple and easy-to-use. What is more, the hardness tester can be complemented with the digital image measuring system for faster and easier analysis and measurement of imprints while Brinell and Vickers measurements are made.

Optional imprint measuring camera for Brinell and Vickers scale

The imaging system combines computer software, a microscope, and a hardness tester. Through an easy operation of keyboard and mouse click users can test different kinds of hardness and evaluate the imprint with minimum risk of man-made errors. The camera allows users to directly observe the indentation and clearly and conveniently display it. The measurement and control of the system use a high-resolution microscope to display the indentation clearly on the computer screen.

- 3-in-1 solution for hardness testing by 3 different methods – Rockwell, Brinell, and Vickers

- Touch screen display

- Automatic load application, electric drive, load cell

- Easy and convenient operation and maintenance

- Wide range of hardness scales and test forces

- Multi-functional instrument in its class. User can measure hardness in various scales and have no problems with hardness measurement in a wide range – from very soft materials up to some of the hardest materials

- Automatic calibration on all scales

- Built-in high-precision microscope with internal and external illumination for easy fingerprint measurement

- Special table allows measuring imprint diameters without removing the sample, making work much easier

- Special table which allows user to measure the diameters of prints without removing the sample from the device

- An electric actuator – the main test load is completely automated

- Data output to PC

- Printing results through built-in printer

- Connection to a digital camera measurement system (optionally)

- Easy menu navigation

- Easy measurement procedure

- High-quality materials and workmanship

- High durability

- Long life

- Warranty and lifelong after-sales support the cover spare parts

- Competitive price

| Indenters |

|

| Test forces |

|

| Scales conversion |

|

| Start load | 10 kgf (98N) |

| Test forces |

|

| Measuring time | 5 – 60 sec, adjustable |

| Testing materials |

|

| Hardness range |

|

| Measurement accuracy |

|

| Max height of test object |

|

| Max depth of test object | 165 mm (optionally up to 200 mm) |

| Microscope magnification | 100Х, 50Х, 25Х |

| Lense magnification | 10X, 2.5X, 5X |

| Data output |

|

| Recommended operating conditions |

|

| Net weight | ~ 70 kg |

| Gross weight | ~ 80 kg |

| Dimensions | 550 x 700 x 850 mm |

- Rockwell conical diamond indenter with a 120° apex angle

- Brinell: Hard alloy steel balls 1.5875 mm, 2.5 mm, and 5 mm

- Vickers four-sided diamond indenter (136 °)

- Standard hardness test blocks

- Microscope

- Lens

- Large testing table

- Medium testing table

- V-shaped testing table

- Movable testing platform

- Bolt adjusters

- Fuse

- Power cable

- Optional imprint measuring camera for Brinell and Vickers scale

- Digital Universal Hardness Tester NOVOTEST TB-BRV-D – 1 pc

- Rockwell conical diamond indenter with a 120° apex angle – 1 pc

- Vickers indenter (Four-sided diamond pyramid (136 °)) – 1 pc

- Brinell indenter (1.5875, 2.5, and 5mm hard alloy steel balls)

- Microscope for Brinell and Vickers scales – 1 pc

- Lens (2.5X and 5X) – 2 pcs (1 pc each)

- Large testing table – 1 pc

- Medium testing table – 1 pc

- V-shaped testing table – 1 pc

- Movable testing platform – 1 pc

- Rockwell Hardness Test Blocks:– HRC – 2 pcs – HRB – 1 pc

- Brinell Hardness Test Block HB – 1 pc

- Vickers Hardness Test Block HV – 1 pc

- Bolt adjustor – 4 pcs

- Power cable – 1 pc

- Fuse – 2 pcs

- Operation manual

- Calibration certificate

- Transportation box

+38 067 593 59 77

+38 067 593 59 77