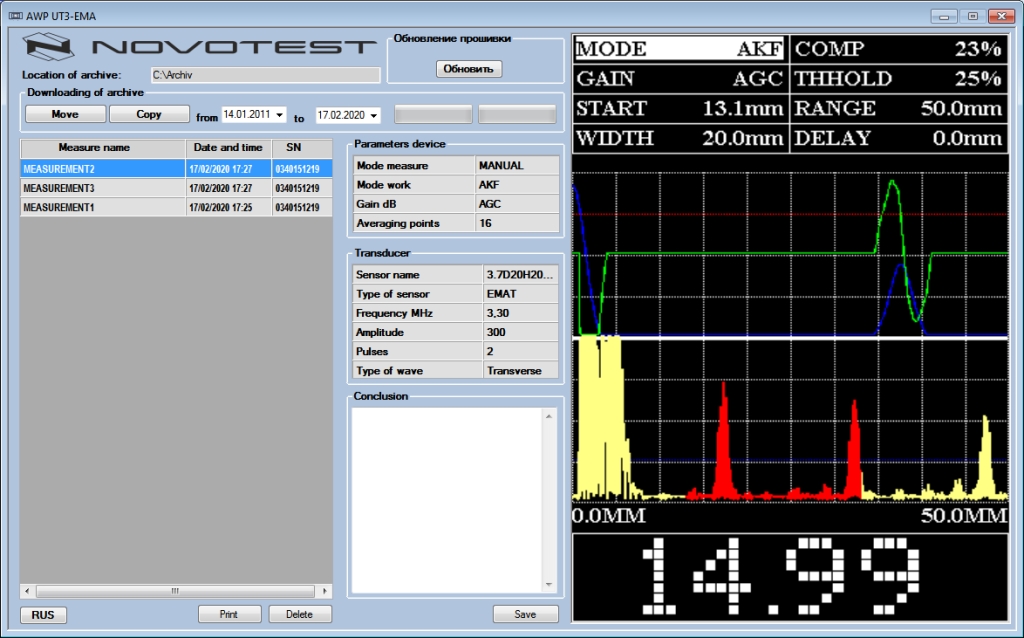

EMAT Thickness Gauge NOVOTEST UT-3M-EMA is a new development of the NOVOTEST company, which will allow our users to solve not only the standard tasks of testing the thickness of metal products, but also to carry out tests in cases where traditional methods, such as piezo-ultrasonic, laser-optical, X-ray, mechanical, etc. – not applicable.

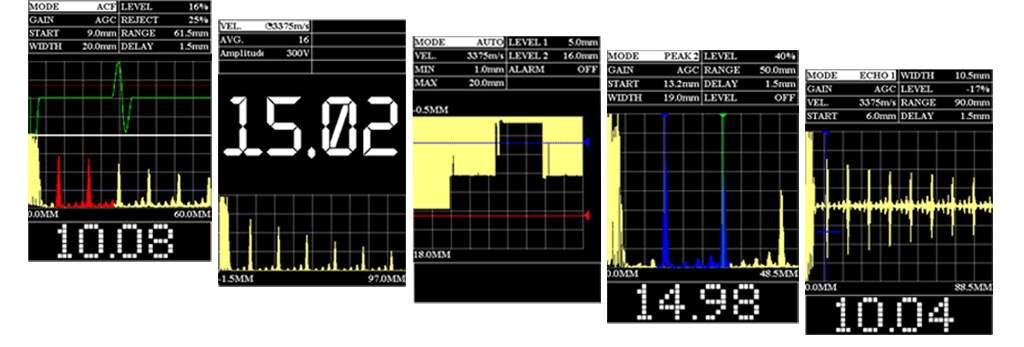

Electromagnetic-acoustic (EMA) technology for measuring thickness is based on the excitation of ultrasonic waves in the material by the generator of the device’s probe, and fixing the path time of ultrasonic waves in the material.

+38 067 593 59 77

+38 067 593 59 77