With NOVOTEST Lab App you are able:

– setting and calibration of the hardness tester;

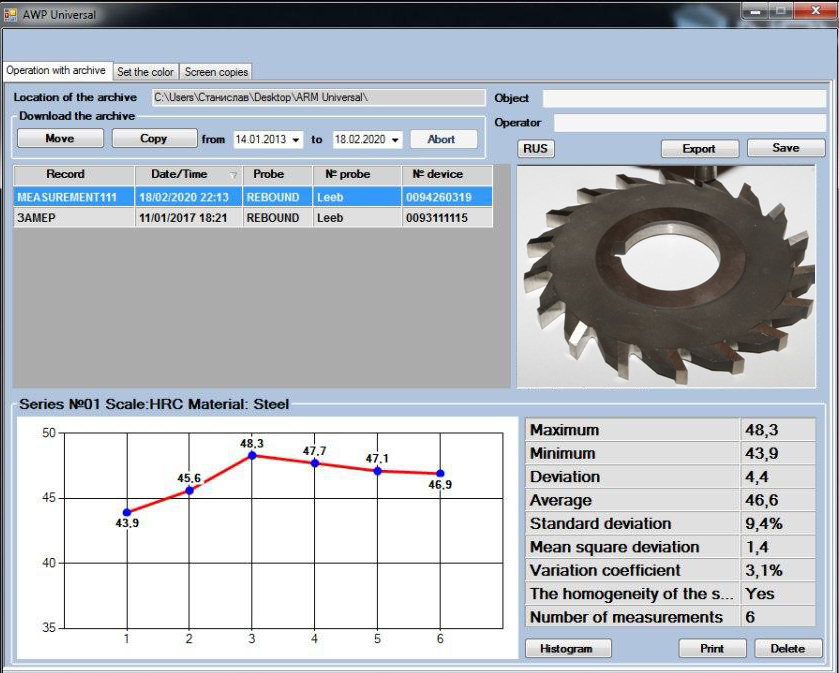

– display of measurement results in real time in numerical form with the construction of a graph, histogram or statistics;

– take a picture of the test object with the puting of hardness marks;

creation of a video of the controlled product;

– recording audio notes fro the tested object;

– automatic saving of measurement geolocation on Google maps;

– displaying a Google map with markers of places of measurements made on it and the ability to view these measurements;

– displaying the calendar of measurements (presentation of the archive in the form of measurements grouped by date);

– formation of the final comprehensive report on the measurement;

– sending a finished report to e-mail, messenger (or in any convenient way) directly from the application;

– flexible structure of the archive of measurements – completely similar to the usual explorer, with the ability to create folders and files with any names;

– synchronization with PC and other smartphones;

– cloud service for storing the archive of measurements;

– automatic and manual synchronization of cloud measurement archives between devices;

– launching the Google navigation mode, building a route and accompanying to the point at which the measurements were made

– the ability to store archives of other devices with Bluetooth in one application.

+38 067 593 59 77

+38 067 593 59 77