Rockwell Hardness Tester NOVOTEST TS-R-C

Digital Rockwell hardness tester TS-R-C implements direct Rockwell method of hardness testing in accordance with ISO 6508-2 and ASTM E18.

Application

Rockwell Hardness Tester NOVOTEST TS-R-C allows user to measure hardness of:

- hardened and surface hardened steel, hardened and tempered steel;

- cold and hard casted parts, forged parts;

- hard alloy steel;

- aluminium alloys;

- bearing steel;

- carbonized steel sheets and others.

Description

Digital Rockwell Hardness Tester NOVOTEST TS-R-C is a digital model with new-designed large LCD screen to display the structure of menu. The bench Rockwell hardness tester has the hyper terminal setting RS-232 with good reliability, excellent operation and easy watching.

The Rockwell hardness test uses the method of measuring indentation depth. The hardness values are read directly through the LCD screen. Therefore, it is easy to operate the hardness tester with high efficiency. The hardness tester is suitable for inspect batches of spare parts. Digital Rockwell Hardness Tester NOVOTEST TS-R-C allows to use the diamond indenter and ball indenter, which can measure the hard and the soft samples. So, it has been widely used in production to become the most detecting device for inspecting the product quality and determining the reasonable processing technology.

Digital model has following advantages against analog machine:

- more convenient in operating;

- measurement process is faster;

- setting menu is easy in use (setting of scales, loads and dwell time etc.);

- digital resolution is better. As a result, accuracy is higher than manual tester has;

- RS-232 interface;

- human factor influence is minimum.

The machine allows user to:

- select the Rockwell hardness scales type (A, B, C, D, E, F, G, H, K);

- recalculate the obtained hardness values into all hardness scales (Brinell, Rockwell and Vickers);

- record test results under the particular operator;

- print the results of hardness measurements via built-in printer;

- automated load/unload system allows user to get measurement results of high accuracy and free of operator faults.

| Indenter | Conical Rockwell diamond indenter (120 °): diamond tip as a cone with 120 degrees of the cone apex angle and the bead size of 1/16 inch (1.5875 mm) |

| Scales |

|

| Hardness resolution value | 0.1 |

| Measurement accuracy | <1.0% |

| Conversion scales | Plastic Rockwell, Brinell, Vickers |

| Initial testing load(accuracy ±2%) | 98,07N (10kg) |

| Testing load (accuracy ±1%) |

|

| Measuring time | 5~60 sec |

| Testing materials |

|

| Max height of test sample | 100 mm (210 mm – without protective cover) (can be produced up to 400 mm) |

| Max depth of test sample | 165 mm |

| Power supply | 220V±5%, 50~60Hz |

| Data output |

|

| Recommended operating conditions |

|

| Net weight | 86 kg |

| Gross weight | 96 kg |

| Package dimensions | 630*500*860 mm (L*W*H) |

- Indenters

- Standard hardness test blocks

- Large testing table

- Medium testing table

- V-shaped testing table

- Bolt adjustor

- Power cable

- Fuse

- Rockwell Hardness Tester NOVOTEST TS-R-C

- Conical Rockwell diamond indenter (120 °)

- Hard alloy steel Rockwell ball indenter (d=1,5875 mm)

- Large testing table (d=150 mm)

- Medium testing table (d=60 mm)

- V-shaped testing table (d=40 mm)

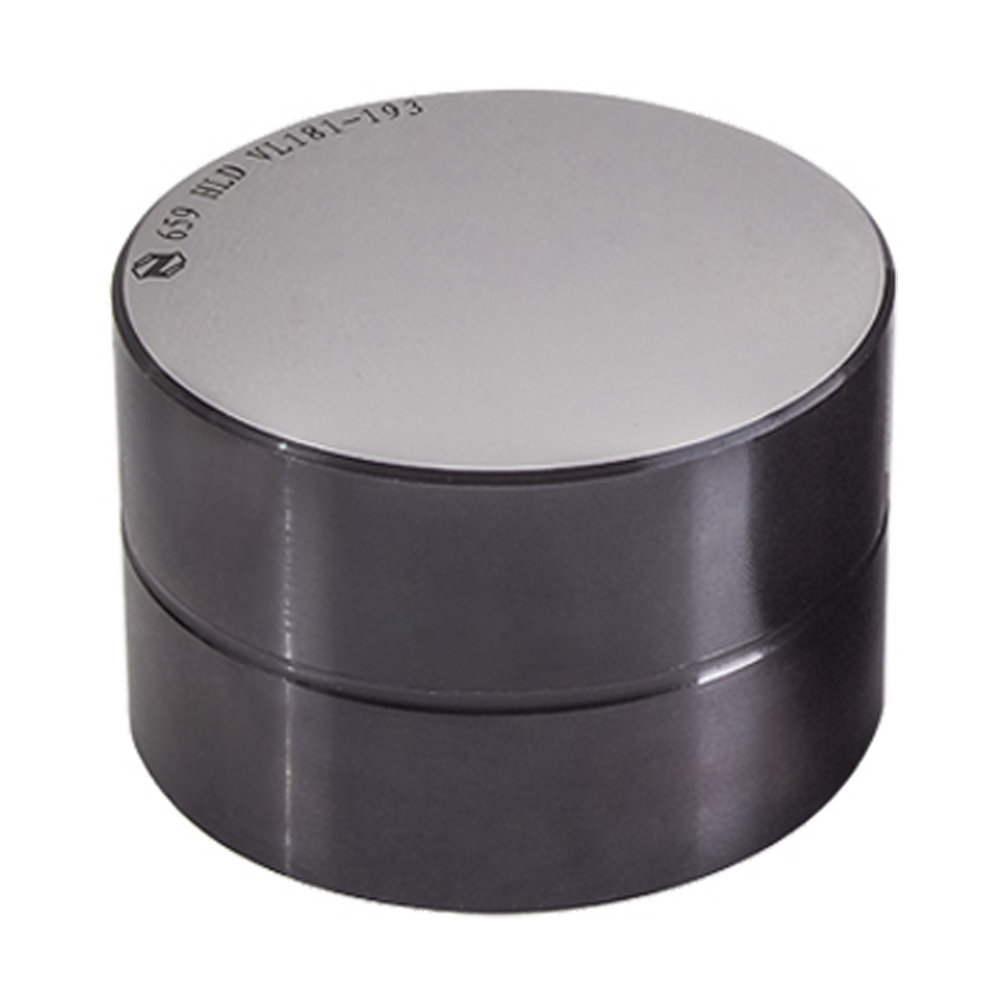

- Rockwell hardness test blocks (5 pcs. in total):

HRA: 85±5 – 1pc.

HRB: 90±5 – 1pc.

HRC: 65±5 – 1pc.

HRC: 45±10 – 1pc.

HRC: 25±5 – 1pc.

- RS-232 interface

- Bolt adjustor (4 pcs.)

- Power cable

- Fuse (2pcs.)

- Operating manual

- Calibration certificate

- Transportation box

+38 067 593 59 77

+38 067 593 59 77